We deliver confidential, unbiased recommendations.

Every project has unique features and requirements. We uniquely combine analysis and research with the experience of industrial practice. Our spray consulting with clients rapidly develops practical solutions to their problems. We use a variety of tools, beginning with spreadsheet calculations, to understand the impact of change, coupled with your process knowledge to prioritize critical issues.

Consulting service examples:

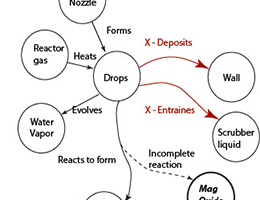

- Process Improvement: Evaluate the potential and the benefits for process improvements in production plants and research facilities. For example, we evaluate a spray dryer system to increase capacity and improve product consistency.

- Development and analysis of experimental and modeling programs: to produce rapid and robust conclusions. Validating a design and understanding the limits of operation are often critical to rapid and low-risk implementation.

- Design and development of custom nozzle applications: Some systems must have a custom designed nozzle to achieve specific and unique requirements of materials of construction and spray characteristics.

- Equipment Specification: Develop, assess, and review spray equipment specifications for new or modified facilities.

Consulting service benefits to you:

- Reduced risks for commercialization or scale-up

- Solutions for complex fluid dynamics including atomization, multiphase flow, turbulence, and cavitation.

- Increased production and productivity

- Waste reduction

- Incorporation of leading-edge technology

Services Portfolio

-

Analysis

The selection of a nozzle is more than just “choosing a spray nozzle from the catalog.” There are over 500,000 nozzles and capacities in production by the major spray nozzle companies. Which is best for your usage? Misconceptions often limit how well we practice the art and science of engineering. Without state-of-the-art knowledge of the fundamentals and the “rules of thumb,” the technology can be misapplied.

One question people struggle with is: Which type of spray nozzle will help me optimize my process—--pressure or single-fluid, two-fluid (air atomized) or ultrasonic?Examples

Assessment of the impact of changing from a two-fluid spray nozzle in a spray drying application to a single-fluid nozzle

Benefits

Projects often begin with analysis or preliminary analysis of the issue as presented. Preliminary analysis begins with a wide view of options and constraints. Experience with a broad range of applications allows for rapid assessment.

-

Evaluation

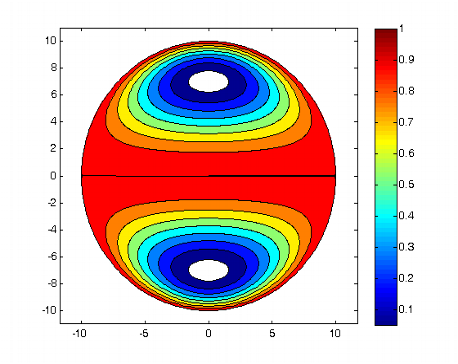

Evaluating spray nozzle systems requires a quantified spray performance. We provide services to test directly, or through third parties, the performance appropriate to your system. We use a number of tools to analyze spray systems, including experimental spray quantification and computational analysis. Our approach to resolving an issue is to apply the least complex and least costly method first. We provide the experience to select the correct measurements and to select the right tools for your project. Physical modeling to determine the appropriate measurements of required spray characteristics is often required. Computational modeling of the process often provides insights into aspects where measurements are too difficult and costly.

Examples

- Physical patternation

- Drop size distribution measurements

- Spray angle

- Spray photography and videography

Benefits:

- Quantitate data comparing different nozzles or operating conditions

- Optimum spray system

- Improved process control

-

Development

In many projects the bulk of time is spent in developing the detail of potential solutions, evaluating the feasibility, and determining potential problems. This work often involves the evaluation of data to extract the greatest impact.

Designing experimental programs and analyzing the results are essential to optimizing the solution set.

Examples:

- Equipment Specification: Develop, assess, and review spray equipment specifications for new or modified facilities.

- Process Improvement: Evaluate potential and benefits for process improvement in production plants and research facilities. For example, we evaluate a spray dryer system to increase capacity and improve product consistency.

- Development and analysis of experimental and modeling programs to produce rapid and robust conclusions.

- Design and development of custom nozzle applications.

Benefits:

- Reduced risks for commercialization or scale-up

- Solutions for complex fluid dynamics including atomization, multiphase flow, turbulence, and cavitation

- Increased production and productivity

-

Training

Engineering and technical training are essential, in providing fundamental operating principles and the in-depth practical understanding of how systems operate. Training programs designed and focused to address a specific situation and set of objectives can generate a high return on investment. We emphasize the practical aspects built on an understanding of the fundamentals. Focused instruction is essential and vital to a highly successful organization given the pace of change in the industrial environment.

Training Examples

- Spray Technology

- Spray Absorbers

- Vacuum Pump Troubleshooting

- Chemical Processing Essentials

Benefits

- Increased plant throughput

- Increased “on-spec” product

- More rapid decision-making

- Avoiding technology dead ends